|

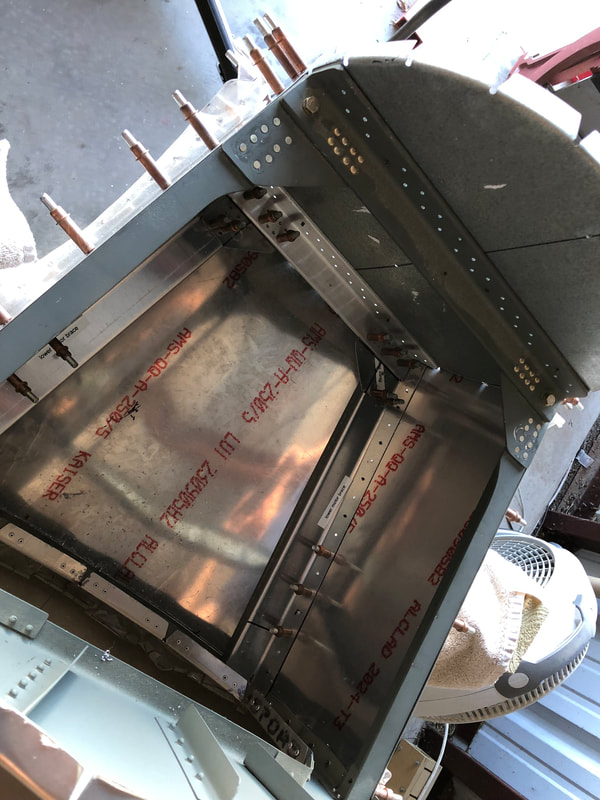

still working on the center spar. Purchased some 5/32” riveting supplies. And got most of the rivet holes marked out.

0 Comments

the spar cap on the right is correct. The one on the left should be flush against the outer cap. I slipped with the router and tried to sand the gouge out, but it took to much material off.

spar web should be 4 1/32” not 4 5/16” due to the .1875” radius of the spar cap. The inner spar cap is easy to fit by just using a 3/16” roundover bit set .040 too shallow.

spent an hour on Sunday putting the notches in the spar caps. Just rough cut them. I will sand the to the correct dimensions this week.

Also saw a video posted online of my ribs being formed up. It’s a tremendous time saver for me. ordered a cframe riveter/dimpler as well. Turns out it is back ordered with a two week lead time. This will put me into February to finish the spars, but at least everything else is ordered and I still have some parts I can form up. Built the spar jig together tonight. It was simple enough, flat and straight as an arrow. Built as a t with a center stiffener glued up underneath that won’t interfere with the clamps.

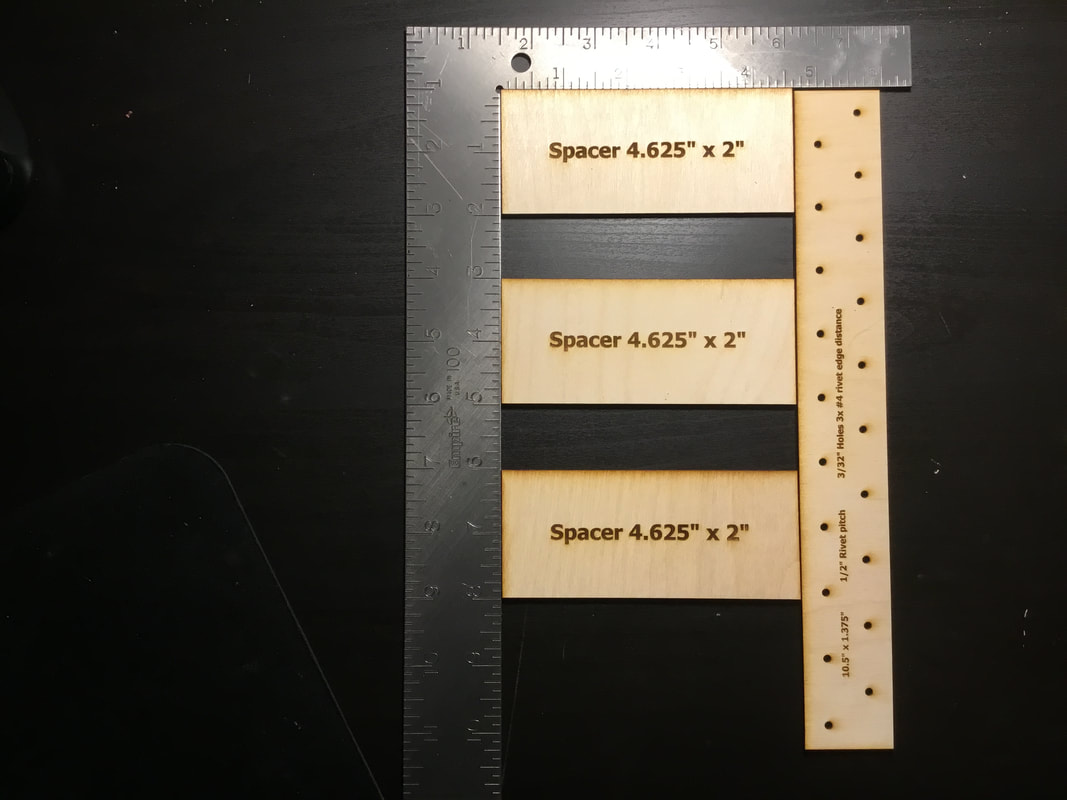

Purchased a Chinese laser cutter last year. Been making all kinds of things with the help of my wife. She did some amazing ornaments. Laser-cut wedding invitations, all sorts of stuff. The things I make are more building and aviation related. So I made some spacers and rivet spaces to help me out while building. Being able to work on things from home should help keep me motivated.

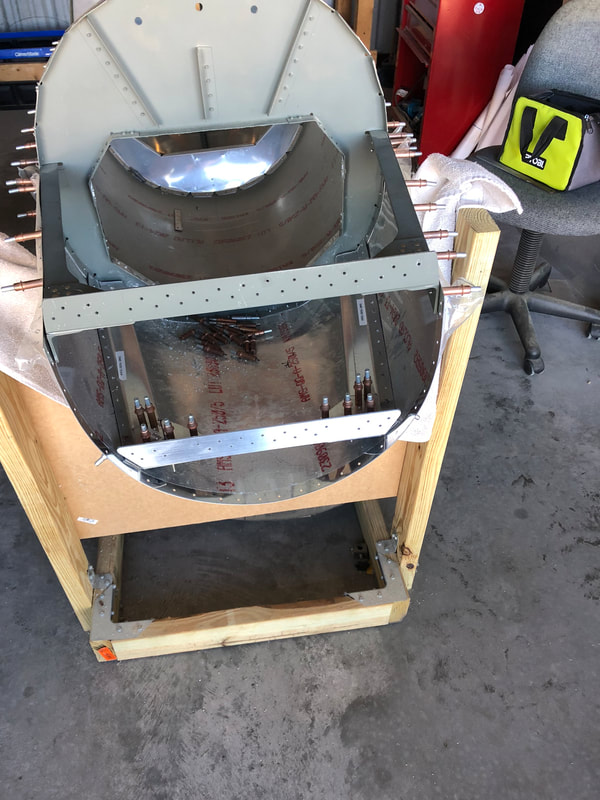

Finally came to the conclusion that no one is going to let me use their tool to cut and bend the spar webs, and the horizontal and vertical stabilizer spar. I got in touch with Terry From Hummel Aviation and he is going to cut and bend them for me. I also decided to have them fabricate the wing ribs for me. All for about $1,000 shipped.Life is strange. When I started this i had more time than money. Now things have flipped the other direction. At least I can buy parts now though, up until 2017 I really had to save to buy a sheet of metal...

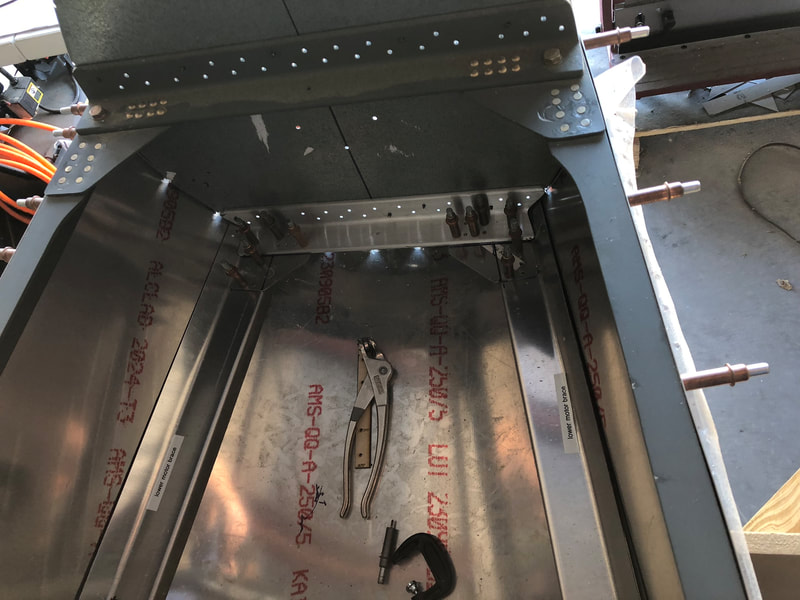

Tomorrow I should receive the aluminum angle, 6061t6 sheet, and steel needed for the wing spars. I've already gathered and cut the material needed for the jig. I'll just need to assemble it tomorrow. A quick note about how over built this airplane is. Terry got with an engineer due to my request and found that 6061t6 is more than strong enough for the spar webs and spars. Thought I could get the two Motor mount stringers finished in an hour. It took 3 hours of continuous work, But everything is drilled and fit to the final size.

|

AuthorHello I'm Adam Hied, 31 years old and I am slowly building a hummelbird Archives

November 2020

|

RSS Feed

RSS Feed