|

Not much to report today. Openend all the holes up, deburred and dimpled them. Other than the ones around bulkhead E Which I will dimple during that bulkheads final install. I am also adding a new section to the site for plans errors.

The horizontal stab reinforcing plate is shown in the plans as being on the outside of the skin. Several sources say it should go on the inside. I already made bulkhead E and after talking to Terry at Hummel Aviation I decided to leave it on the outside Total Time Today - 2.5 hours

0 Comments

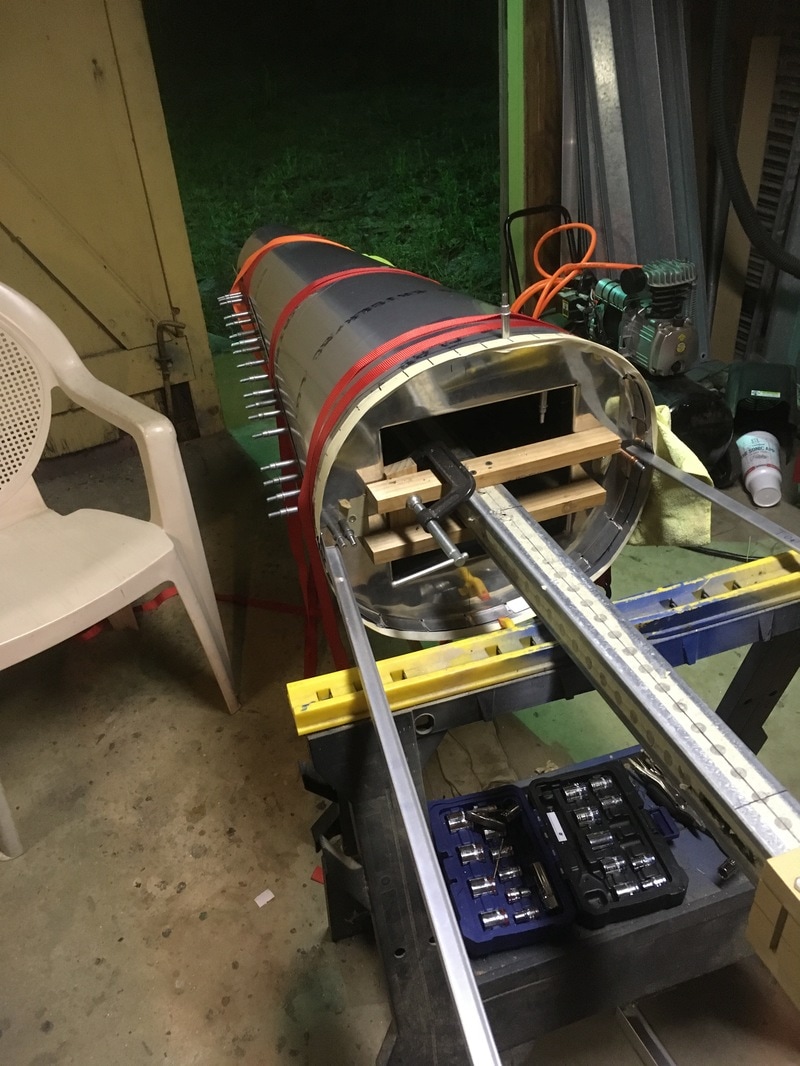

Spent some more time working on the airplane last night and today. Probably 6 hours of actual work. Finished drilling all the holes in the skin. Drilled all the stringer holes to a #30 hole size. Removed the skin again to trim to a better fit, deburr and back drill a couple holes. Deburred and smoothed the edges with scotchbrite pads. While it was off I decided to prime all the mating surfaces. Then I got lucky because a package came from aircraft spruce. another $200 spent on clecos, avex rivets, a rivet squeezer, a blind dimple die, and something else I can't think of off hand. Because of that I was able to prime and rivet several brackets to bulkhead D and E, and the stiffeners to bulkhead D The past week has been spent working on skinning the fuselage from bulkhead e to d. I'm hoping to complete this section Friday. Then hopefully begin the process of riveting. Rolling the .020 sheet into such a tight cone proved to be a little more difficult than I thought. In the end some ratchet straps helped me win the battle. To date I have about 12 hours into just this fuselage skin.

I have just a little bit of trimming, deburring, and a couple hole to back drill. Them I'll get it all primed and ready to go. I've decided to migrate my build log from blogger to weebly. For the sake of simplicity below is the rss feed from my old blog with full text. Basically, since 2014 I haven't done a whole lot with my project. Today I have completed my last day at the Florida Institue of Technology with a B.A. Aviation Management. I already have been working in the field for five years so new job prospects are good. I'll also be able to devote 50-80 hours a month to working on the hummelbird. To date I have made all the bulkheads, secured them to the alignment beam. Measured once, measured twice, then 15 more times. As of this week I have begun making the tailcone skins from e-d. I will add the pictures to this post at a later date. |

AuthorHello I'm Adam Hied, 31 years old and I am slowly building a hummelbird Archives

November 2020

|

RSS Feed

RSS Feed